griffin

engineered for dtg curing

features

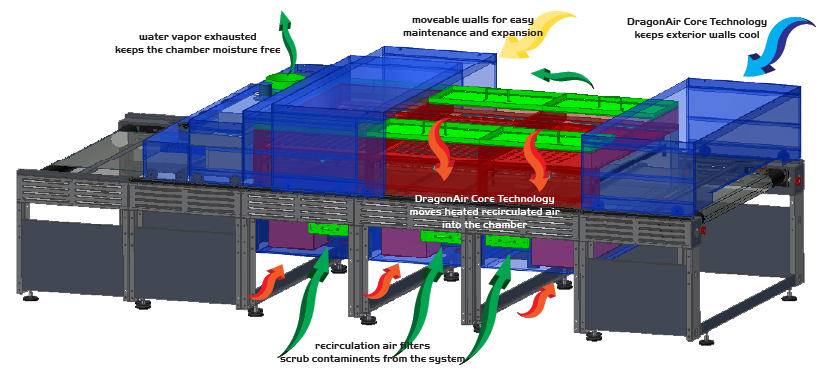

- DragonAir Core Technology

- TRX control software

- Touchscreen operation

- Variable speed air flow

- Easy accessibility for maintenance

- Belt speed adjust from .01 second to 99 minutes

- Modular design for expandability

downloads

The DragonAir Fire is designed to fit the needs of the large direct to garment printer. Using DragonAir Core Technology, the Griffin captures and scrubs heated air and maintains internal temperatures while keeping a cool outer skin. The kiosk contains a touchscreen and provides quick changes to 18 different product profiles and immediate access to oven settings and maintenance tasks.

Standard Brown heavy-duty construction promises reliability and consistence for years. The belt speed is variable from 00:01 seconds to 99:99 minutes for complete flexibility for either DTG ink or pretreat. Variable air flow is adjusted within the profiles of the touchscreen controls, allowing for flexibility of ink and pretreat types. The air is scrubbed for particles to keep the internal systems operating at peak efficiency.

The Griffin is fully expandable for production growth. Additional heat sections install to double production and these are controlled within the same kiosk The roller track design simplifies maintenance accessibility and the calrod heaters are warranted for 7 years. This high volume DTG curing oven is a nice fit for a 4 DTG shop with high hopes for the future.

| DragonAir Griffin | DAG-4860 | DAG-4890 |

|---|---|---|

| Belt Width | 48" | 48" |

| Belt Length | 150" | 180" |

| Infeed | 30" | |

| Exit | 30"" | 30"" |

| Core length | 60" | 90" |

| Power requirements | 240VAC, 57A (x2), 1Ø or 240VAC, 66A, 3Ø | 240VAC, 99A, 3Ø |

| Overall Dimensions | 85" x 150" x 70" | 85" x 180" x 70" |