Control system module

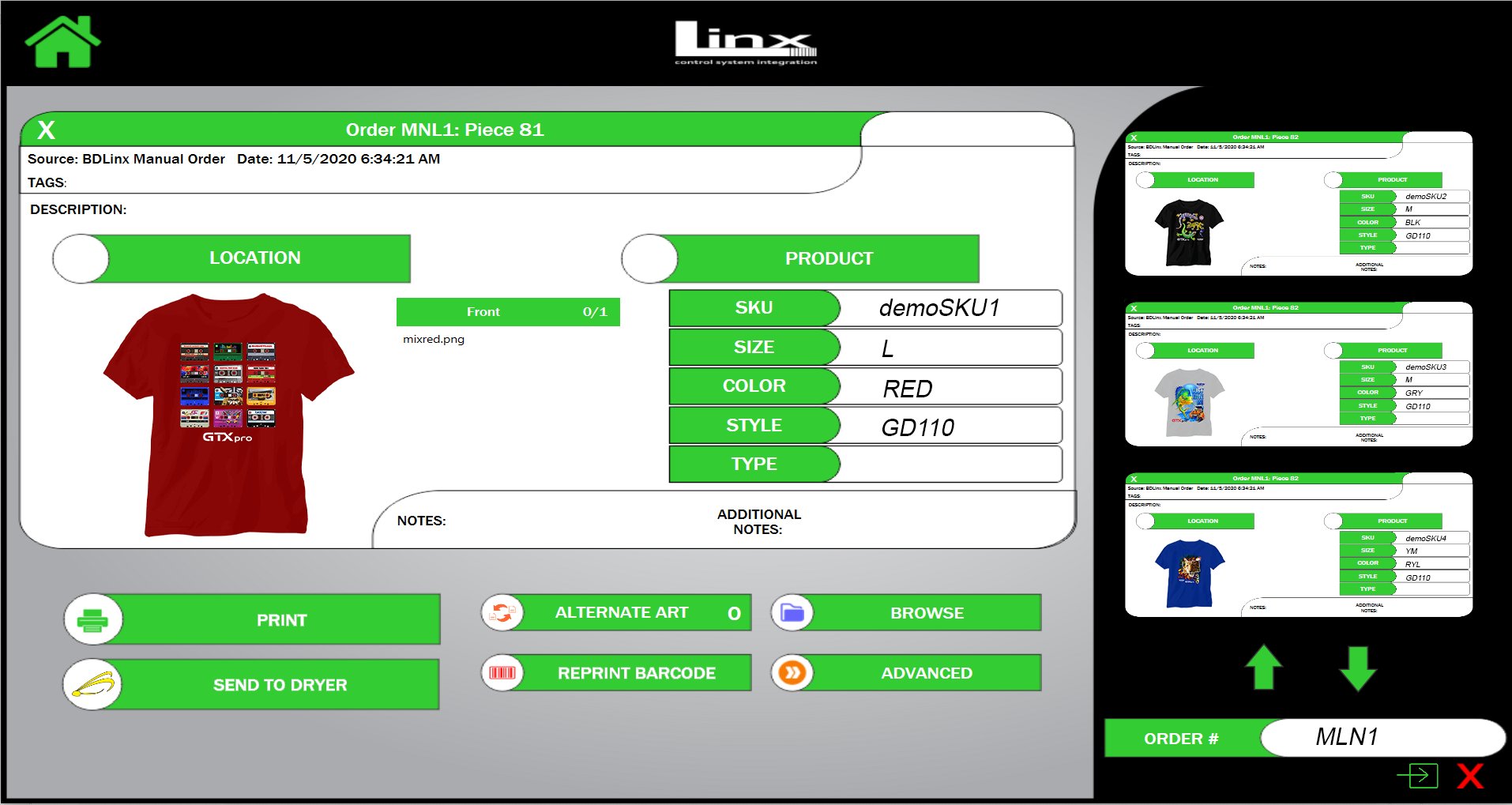

member of the Linx Software Suite

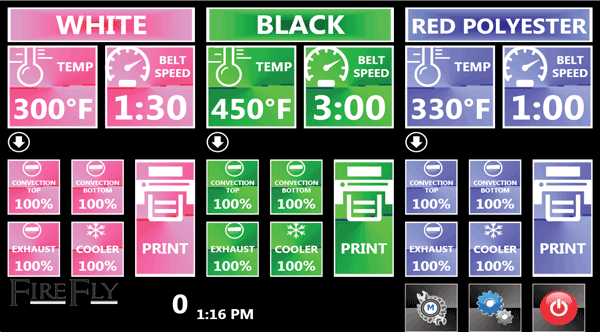

FireFly Control features

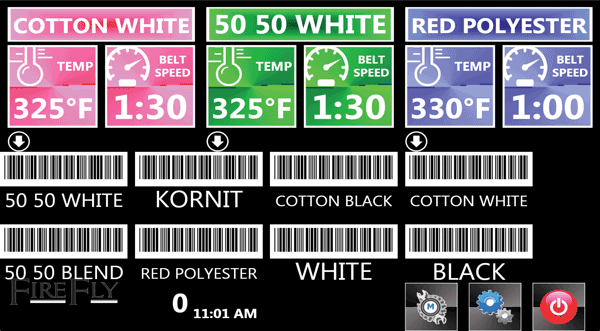

- Barcode scanner for each lane

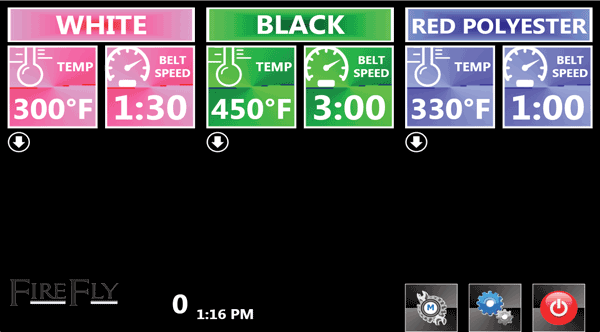

- 32" heads up video display

- Barcode printing device

- Barcode processing response

- 36 stored profiles

- 18 stored maintenance tasks

- Job cost analysis

- Independent lane control

- On-board diagnostics

- Connection to the full Linx Suite

downloads and links

With the use of 36 stored curing profiles, each garment moving through the FireFly can be cured individually. As a garment is loaded it is detected by the FireFly. The operator can choose to use the currently running profile or select a different one with the touch of a finger or a scan of a barcode. This quick change is immediate with each garment and allows for multiple different cure profiles to run through the same chamber, one right after the other.

The FireFly software profile store information on temperature, belt speed, convection air, exhaust air and exit cooling. These parameters are specific to garment, ink or process and instant repeatability provides a higher quality of finished good because of consistency of cure. All of the parameters of the profile can be shown on the heads up display and the kiosk.

The software also tracks job costs and power consumption analysis. Owners have all the tools they need to properly track their cost of good sold. The FireFly has an on-board diagnostics system that monitors all of the functions of the oven and provides operator alerts.