FireFly Curing System

patent number 10,011,136

firefly features

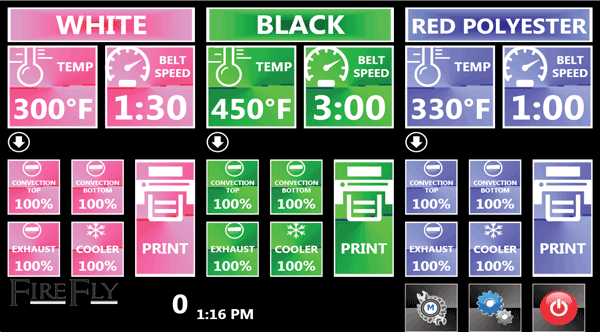

- FireFly Linx control module

- Thermal imaging cameras

- Continuous monitoring of substrate

- Quartz heat for rapid reaction

- Instant on/off eco cycle

- Touchscreen or barcode scanner control

- Variable air controls per lane

- Garment temperature monitors

- Roll-away track design for maintenance

- Multi-belt design

- Thermal imprint screen for product monitoring

- Automatic speed calculations per garment

- Heavy-duty drive train

- Belt speed increments from .01 to 99:99

- Expandable for growth

downloads and links

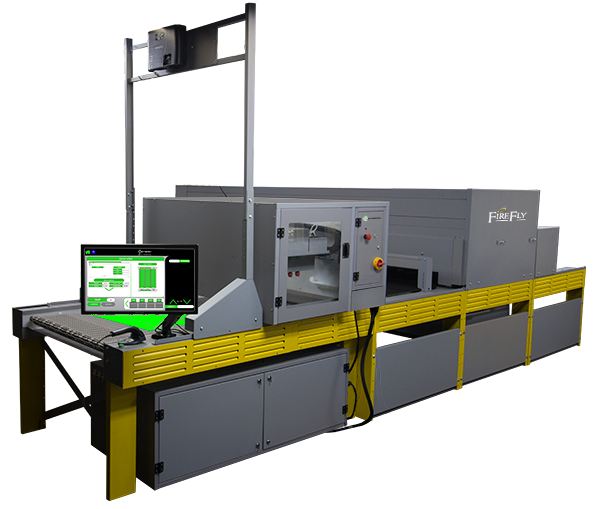

The patented FireFly curing system is unique. Every garment is managed as a individual item for optimal cure and control. Thermal imaging cameras constantly monitor substrate temperature and cycle the quartz heaters to keep the garment at or below the defined profile temperature. These temperatures are displayed on a side monitor for easy user access.

Standard Brown construction is heavy duty with details found on the drive train, the main chassis and the easily accessible heat drones. Track systems for roll-away maintenance make this machine simple to maintain and the touchscreen and scanner controls give it an amazing ease of use. The units are expandable in length to provide growth and flexibility to any shop.

The revolutionary design of the FireFly gives it flexibility to service many parts of the garment decorating world. With temperature monitoring there is a dramatic reduction in dye migration on athletic wear. With varied controls of the air flow, this unit is a perfect fit for water-base and discharge production. The possibilities are endless.

| FireFly | FY1x36-45 | FY2x36-45 | FY3x36-45 | FY2x27-45 | FY3x27-45 |

|---|---|---|---|---|---|

| Belt Width | 36 | 36 | 36 | 27 | 27 |

| Working Belt Width | 34 | 34 | 34 | 25 | 25 |

| Belt Length | 135" | 135" | 135" | 135" | 135" |

| Chamber Length | 45" | 45" | 45" | 45" | 45" |

| Infeed | 45" | 45" | 45" | 45" | 45" |

| Exit | 45" | 45" | 45" | 45" | 45" |

| Lane Count | 1 | 2 | 3 | 2 | 3 |

| Overall Dimensions | 62" x 135" x 68" | 107" x 135" x 68" | 162" x 135" x 68" | 89" x 135" x 68" | 125" x 135" x 68" |

Synergy Pretreat

Professional, industrial, consistent pretreat system that combine with the FireFly for full system print-on-demand production.